Industry

- Factory Automation

- Required to update the old automation systems

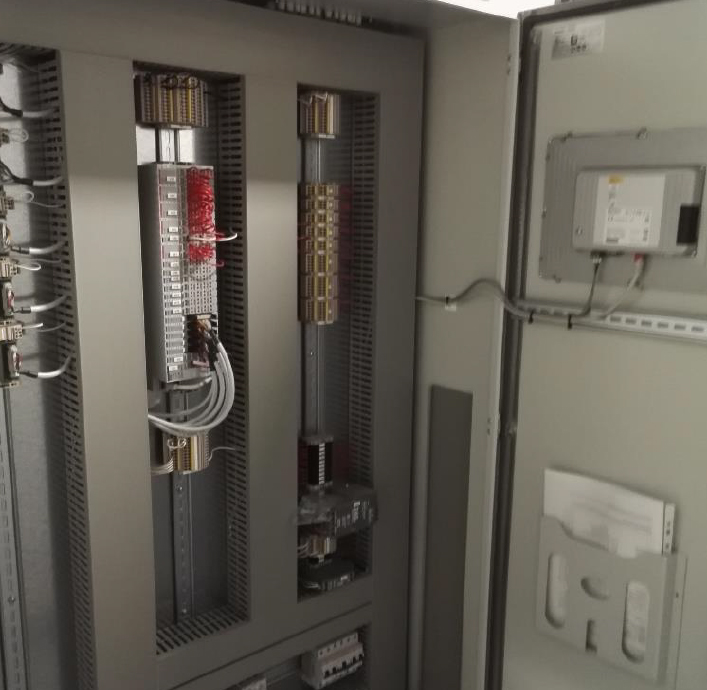

- Looking for a smart cabinet with cost-effective items

Solution

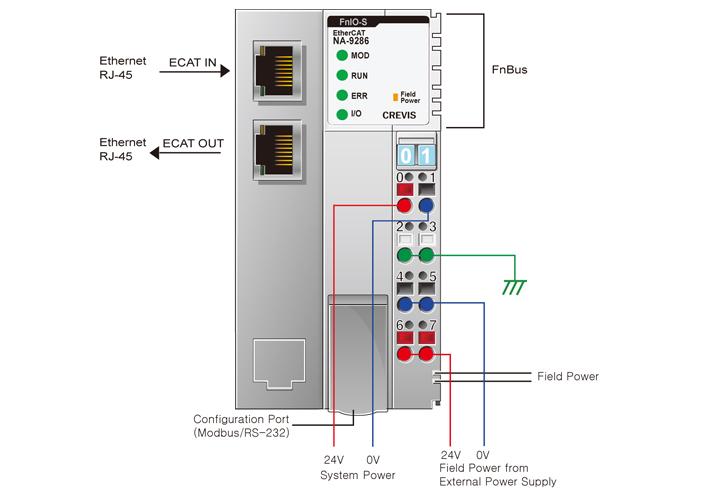

- Configured with Beijer X2 Control 12 + Crevis NA-9286 & I/Os

- Selected EtherCAT for the fast communication

- Added ST-3702 for PT1000 meat sensors to control temperature in the freezer

Results

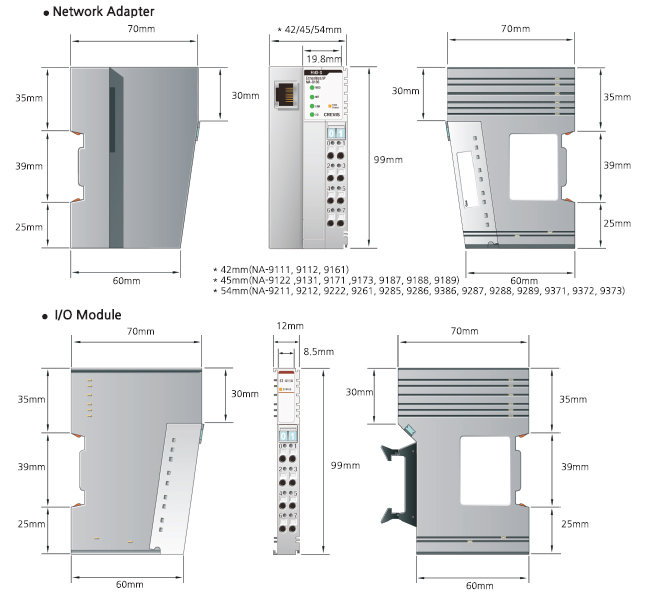

- Cost & Space-saving from the slice type I/Os

- Easy installation and maintenance

- Satisfied with these compact fast systems

- Decided to expand the new technologies to the barbecue production lines recently

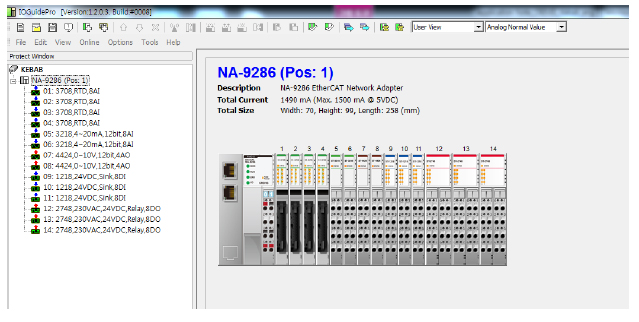

IO Configuration or Module explaination

*More options available depending on customers’ demands

- Easy configuration in Crevis’ I/O Guide Pro

Project Info

- PLC: Beijer Electronics X2 Control 12

- Crevis S-Series I/O configuration (TOTAL 1,000 I/O points)

•Network Adapter: NA-9286 (EtherCAT)

•DI: ST-1218

•DO: ST-2748

•AI: ST-3218, ST-3708 (with PT100 and PT1000 meat sensors)

•AO: ST-4424